UK Health and Safety regulations

When it comes to working in high-risk situations or industries, we as people must be as protected as possible. This is why there are a variety of UK Health and Safety Regulations. These are set out to ensure that anyone who is most at risk has everything that they need (be that equipment or knowledge) to keep themselves and those around them as safe as they can.

Some examples of the regulations that you may need to be aware of include:

However, there are a variety of other options that you may need to be aware of and follow.

Understanding UK Health and Safety Legislation

If you are responsible for employees and others in a working environment, then you are going to need to fully understand the relevant and current UK Health and Safety Legislation pieces. However, everyone in the workplace needs to be able to understand even the basics of the legislation.

This will allow them to make appropriate decisions for themselves and make sure that they can take charge of their safety, as well as the safety of those around them too.

The Health and Safety at Work, etc. Act 1974

The main piece of legislation that you will need to be aware of is The Health and Safety at Work etc Act 1974. This is the most basic and overarching of the health and safety regulations. It can be known as the HASAWA or the HSW and the majority of the other legislations out there that relate to health and safety will have its beginnings within this regulation.

For the most part, HSW is based on safe practices, with some common sense mixed in. It states that the responsibility for health and safety within a workplace is largely placed on the employer rather than the employee. Although this is identified as being as far as is reasonably practicable (which means that it is also down to the person to be able to recognise and implement safe working practices).

The key aspects of HSW that relate to employers are:

- Providing safe systems of work and ensuring that they are maintained

- Providing staff members with appropriate health and safety training and inductions

- Ensuring that work equipment is safe

- Provide a safe place to work

- Ensure materials are handled, transported, stored and used safely

- Communicate with safety representatives when needed

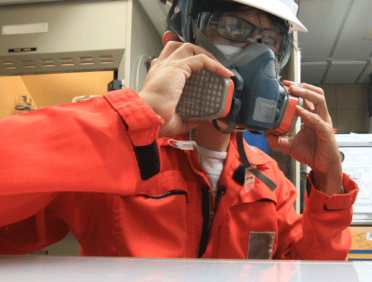

- Provide adequate PPE

As well as this, the HSW outlines that employees should:

- Take care of their safety and the safety of those around them

- Not interfere with equipment designed for health and safety

- Always cooperate with their employers in matters of health and safety

Encouragement for employers and employees to prioritise working at height safety

When working at height, both employers and employees must be aware of what is needed and what can happen if they do not follow the proper guidance. By encouraging them to prioritise safely working at height, they will have the best chance of keeping their employees, themselves and those around them as safe as possible.

Safe Working practises

One of the key aspects of working at height is to identify and then follow safe working practices. These are there to keep people safe and to ensure that the work that is carried out is as risk-free (or has as low risk) as possible.

Let’s take a look at some of the safe working practices for working at height.

Preparing the work area and establishing controls

Any work area that is at height must be properly prepared and assessed before the work is carried out. The reason for this is that the area can be set up in a way that is going to allow for the risk of injuries to be reduced and for it to be as safe as possible.

It is at this time that you may decide to establish control measures. These will depend on the work that is being carried out, however, it should look at a variety of key aspects. These include:

- Carrying out the majority of activity on ground level (where possible)

- Ensuring that the move between the working area and ground level is as safe as possible

- Checking that equipment is suitable for the work to be carried out

- By providing solutions to stop employees from overloading themselves or over-stretching in the working area

- Take precautions if the working surface is fragile

- That they are protected from falling objects

- That there are emergency evacuation procedures in place

All of these control measures are there to ensure that not only the workers are kept as safe as possible whilst they are at height, but also that those in the area are kept safe too.

Site-specific risk control measures

As well as there being more general control measures that you can take when it comes to working at height, there are additional risk control measures that will be more site-specific. These will need to be identified by you, as you are aware of your site requirements and what could be the biggest risks too.

Implementing effective emergency procedures

Whilst the main aim of the working at height regulations is to prevent any issues from occurring, there are still times when an emergency can happen, which means that you are going to need to implement effective emergency procedures.

This may come in the form of a rescue plan, which will identify what needs to happen to ensure that those who are working at height can be easily moved down to the ground level so that they can receive care, help and medical assistance that they may need in an emergency.

Minimising risk during work execution

One of the best ways to try and work safely when at height is to identify the risks and then find a way to minimise them as best as possible. You should encourage employees to work at ground level as much as they can and to always use the correct equipment to keep them safe.

You should also ensure that you thoroughly check over the working area, to ensure that it is not particularly fragile and that there are no loose objects that could fall during the work being carried out.

Use of fall prevention and fall arrest systems

Another way to ensure that those working at height are kept as safe as possible is to use fall prevention and fall arrest systems. These are often in the form of harnesses which will be attached to the ladders or lines that the workers are using.

This is twofold because it means that the ladder won’t move whilst being used, also if the person falls from the ladder when they are using it, their fall will be stopped. Keeping them safe.

Proper handling and positioning of equipment

More often than not equipment is going to be needed when you work at height, this equipment must be handled safely. Not only this, but it should be positioned safely too, away from edges or from places where it may fall.

Inspections and Supervision

Another key aspect of ensuring that working from height is as safe as possible is to inspect and supervise the work, the area and the equipment that is used. You want to ensure that it is properly managed and that any rules or policies that you have set out are going to keep those working as safe as possible.

This should be completed regularly, just in case anything changes, or if previous measures that have been taken are no longer working or relevant. Here are some of the key aspects of inspections and supervision of working at height.

Regular inspections of working at height activities

To ensure that those who are working at height are doing so in a safe way it is important to regularly inspect their activities. These, of course, can change over time, but by checking them regularly, we can make sure that everyone is kept as safe as possible in their working environment.

Identifying potential hazards and risks

We cannot plan for risks or hazards if we do not take the time to identify them. This means that one important step when it comes to working safely at height is to make sure that you know what could happen. It isn’t always nice to think about the worst-case scenario, but there are going to be times when the worst case could happen.

Knowing what you can do to stop it from happening, as well as being planning for what you would do if it did, are things that you should always make sure that you do.

Monitoring compliance with safety regulations

Safety regulations are there for a reason. If we follow them, then we are giving ourselves the best chance of staying safe, as well as keeping those others safe around us too. It is important that as an employer or manager, we check that those who are working on the site understand what the current safety regulations are and that they are following them.

If they are not, it may be time to have a refresher course or to remind them of the importance of those regulations.

The role of supervisors in ensuring safety

Supervisors are important when it comes to safety because they are the ones who are in charge of what is happening at that current moment in time. They need to be able to lead by example, monitor activities and simply remind those around them about what is safe to do when they are working at height.

Supervisory responsibilities and competence

Supervisors should always be fully competent in the safety regulations and understand what needs to happen when it comes to behaving and working safely. They should feel comfortable taking on the responsibility of leading others who are working at height.

Promoting a safety culture and addressing concerns

If everyone on the site understands what it takes to work safely, and feels that a safe working culture is promoted, then they will understand and recognise when someone is not working safely, or if the environment is not as safe as it could be.

Those people should feel comfortable and able to address any concerns that they may have when it comes to a working environment.

Incident Reporting and Investigation

Even when things have all been put in place and safety measures and precautions are taken, there is always a chance that an incident or a near miss can happen when working from a height.

If any incidents or near misses happen when working at height, then it is down to those who are in charge to ensure that it is reported and properly investigated.

Reporting accidents and near misses

Any near misses, accidents or incidents in the workplace should be reported to the HSE following the RIDDOR guidelines. RIDDOR is the Reporting of Injuries, Diseases and Dangerous Occurrences Regulations 2013 and this law ensures that a variety of occurrences in the workplace are reported through the right channels.

For working at height many of the things that can happen will fall under RIDDOR including work-related accidents that result in death or major injuries, accidents that affect non-workers and members of the public and also certain incidents that could have caused harm.

RIDDOR reports can be made on the HSE website as soon as possible under the event and must be within 10 days of it happening. RIDDOR reports need to contain the following key pieces of information:

- Date of submission

- The details o the person making the report

- The organisation

- The location, date and time of the incident

- The details of the person involved

- A description of the event and what injury was caused

Conducting thorough incident investigations

Once you have properly reported the incident through the correct channels, you then need to make sure that you investigate what happened. You need to be able to identify what the risks were and whether or not there are things that you can change in the future to stop another occurrence like it happening again.

Identifying root causes and contributing factors

Another key part of the investigation after the incident is looking at the root causes of the incident. Sometimes these are things that are present all of the time, however, they could also be one of the factors that contributed to the incident happening.

Implementing corrective actions and lessons learned

When you have completed your investigation, you will be able to look at the lessons that have been learnt from the incident. You can consider what corrective actions you can put in place in the future and how they will help to stop another incident like it from happening again.

Continuous Improvement and Best Practises

One thing that you should always know when it comes to working at height, or for any other health and safety matter, is that there is always room to improve. Best practices can change over time and as an employer, you need to be able to change with them.

This means that you need to take the time and make the effort to learn and to change certain aspects of the way that you work, to fit with the changes around you.

Learning from past incidents and near misses

One of the main ways to look at how you can improve and change the best practice within your site is to learn from past incidents and near misses. Think about what has happened in those incidences and what could be changed to make them less likely to happen in the future. You may need to change whole parts of your processes, or you may only need to make small tweaks to ensure that everyone is as safe as possible.

Sharing best practises and industry guidance

When you have taken the time to figure out your own best practices, then it is time to share them with those around you. When it comes to sharing best practices, it is also a good idea to share any of the relevant industry guidance that you have alongside this, as this will help your employees to be able to make links between the two.

Engaging with relevant industry organisations and forums

As well as sharing within your business, you can also share on the outside too. It is always recommended to engage on forums and platforms that allow those within the same industry to come together.

You can share with others like you what you have found and the measures that you have put in place, and they too can do the same. You will be surprised by just how much you can learn from those in the same position as you.

Training and Competence

For employees to be able to keep themselves safe when working at height, they are going to need to have the right level of competency to enable them to do this. This means that a key health and safety aspect is to deliver the right training.

Importance of training for working at height

The right training can make a huge difference when it comes to working at height. Those who are working at height will feel confident in what they know and can pinpoint the aspects of their work that could be unsafe or need additional measures to keep them protected.

Not only this but when they have the relevant training, they are going to be able to identify the parts around them that may need to be changed or amended to make them as safe as possible, helping you to risk assess and change the working environment as needed.

Recognised training providers and qualifications

It is vitally important that when it comes to working at height training, the training provider is fully qualified and able to provide you with training that is up-to-date and is relevant to your business too.

Health and Safety Training with Learn Q

Here at Learn Q we have a number of training programmes designed to help you keep your self, your colleagues, your customers and your business safe, including Working at Height.

If you buy 10 or more courses from Learn Q, you will also qualify for our bulk buy discounts.

Or save even more with our money saving bundles such as:

- Trade Health & Safety 2 Course Bundle | £22.50 | includes Asbestos Awareness and Working at Height

- First Aid and Fire Safety Training Package | £17.51 | includes Emergency First Aid at Work and Fire Safety

- First Aid, COSHH and Fire Safety Bundle | £26.24 | includes Emergency First Aid at Work, COSHH Awareness and Fire Safety

- Health and Safety 5 Course Bundle | £40 | includes Fire Safety, Health and Safety at Work, Display Screen Equipment (DSE) Awareness, Slips, Trips and Falls and RIDDOR (Reporting of Injuries, Diseases and Dangerous Occurrences Regulations) Awareness courses

- Health and Safety at Work 7 Course Training Package | £61.25 | includes Fire Safety, Health and Safety at Work, Display Screen Equipment (DSE) Awareness, Emergency First Aid at Work, COSHH Awareness, Manual Handling and Mental Health: Workplace courses

- Health and Safety in Business Training Package | £33.74 | includes Emergency First Aid at Work, COSHH Awareness, Health and Safety at Work and Fire Safety courses

- Health and Safety in Catering Training Package | £34.99 | includes Emergency First Aid at Work, COSHH Awareness, HACCP Awareness and Fire Safety courses