Filter by

Especially in situations involving gas and electricity, guaranteeing safety both at home and at the workplace is quite important. Although our daily lives depend on both of these services, incorrect handling of either one may lead to serious risks. Understanding concepts of electric and gas safety enables one to prevent accidents and maybe save lives.

This course is aimed at providing comprehensive education on safe management and use of these tools.

Electric and Gas Safety

Preventing mishaps and guaranteeing safe surroundings both at home and at work depend on both electric and gas safety. Following safety guidelines, understanding prevalent hazards, and learning the proper emergency protocols will help people greatly lower their risks connected to these utilities.

Participating in an electric and gas safety course will equip one with the required information and abilities to properly and safely manage these resources. Stay safe and informed.

The Importance of Electric and Gas Safety

Strong energy sources with great demand for careful control are gas and electricity. While gas leaks could generate flames, explosions, and poisoning, electrical risks can inflict shocks, burns, and even death. Learning about the correct use, maintenance, and emergency protocols connected to these utilities helps people greatly lower their chance of mishaps.

From homeowners to professionals operating in fields where these utilities are highly used, everyone depends on knowledge of safety procedures.

Understanding Electrical Safety

Basic Electrical Safety Principles

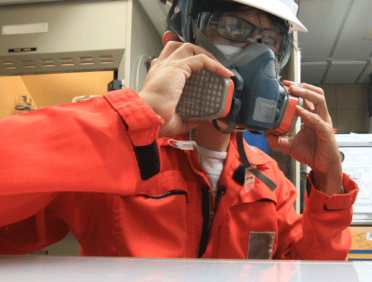

Electricity can be dangerous if not handled with caution. Basic safety principles include turning off power before performing any electrical work, using insulated tools, and wearing protective equipment. It is also essential to understand the role of circuit breakers and fuses, which are designed to protect against electrical overloads and short circuits.

Regularly checking and maintaining electrical systems can prevent malfunctions and hazards.

Common Electrical Hazards

Exposed wires, defective appliances, and overloaded sockets are among the most prevalent electrical hazards. Faulty appliances can short-circuit and start fires, while exposed wires can cause shocks when handled. Overloading receptacles can result in electrical fires and overheating issues.

This can prevent accidents and injuries by being cognisant of these hazards and knowing how to address them.

Emergency Procedures for Electrical Accidents

Should an electrical mishap occur, it is imperative to respond quickly and properly. Should someone be electrocuted, do not touch them directly. Turn off the power source instead, then disconnect them from the electrical source using a non-conductive object. Activate emergency assistance right away.

Use a Class C fire extinguisher for electrical fires; never try to put out one with water.

Understanding Gas Safety

Basic Gas Safety Principles

Gas safety is knowing how to run and maintain safe gas equipment and systems. Make sure every gas appliance is routinely serviced and fitted by a licenced engineer. Use gas appliances as directed by their manufacturer always. Putting up a carbon monoxide detector will give you extra protection by alerting you to potentially fatal leaks.

Common Gas Hazards

Leaks, defective appliances, and inadequate ventilation comprise typical gas hazards. If ignited, gas leaks can result in explosions, and the inhalation of gas can result in severe health complications or mortality. A accumulation of carbon monoxide may result from the inefficient combustion of gas by faulty appliances.

Proper ventilation is essential for the secure dispersion of any gas emissions.

Emergency Procedures for Gas Leaks

Avoid using any open flames or electrical controls if you suspect a gas leak. Ventilate the space by opening windows and doors, and, if feasible, interrupt the gas supply. Immediately evacuate the building and contact the gas emergency services. Return to the building only after a professional has declared it secure.

Frequently Asked Questions (FAQs)

There are numerous regulations in the United Kingdom that govern the safety of employees and the public in the workplace, including electrical safety. Key legislation, such as the Electricity at Work Regulations 1989, delineates obligations to prevent electrical hazards.

The Health and Safety at Work Act 1974 creates a general obligation for employers to guarantee the health and safety of their employees and any other individuals who may be impacted by their operations.

Employers must guarantee the safety of electrical installations and apparatus. Additionally, this encompasses routine electrical system inspections, maintenance, and testing.

Employers are required to provide sufficient training to employees who operate or are in close proximity to electrical equipment to guarantee that they comprehend the necessary precautions and hazards.

The Management of Health and Safety at Work Regulations 1999 mandate that employers conduct risk assessments, which encompass electrical hazards. Employees should be apprised of the hazards and control measures in place, and personal protective equipment (PPE) should be provided as needed.

Safety and efficiency necessitate consistent maintenance of gas appliances. It is generally advised that gas appliances be serviced on an annual basis. This guarantees that they are functioning properly and safely, thereby minimising the likelihood of gas leakage, carbon monoxide poisoning, and other potential hazards.

During a service, a registered Gas Safe engineer will check for gas escapes, test the appliance’s pressure, and verify that it is burning gas correctly. The ventilation and flue will also be inspected to ensure that harmful gases are safely removed from the residence.

When you have your appliances serviced on an annual basis, you can extend their lifespan and make them operate more efficiently, which could result in cost savings on your monthly energy bills.

It is important to keep in mind that certain warranties may require routine maintenance in order to function properly.

A Gas Safe qualified engineer must perform an annual gas safety check on all gas appliances and flues in rental premises. This check is required by law for landlords to have done. Within a period of twenty-eight days following the inspection, tenants are required to get a copy of the gas safety record.

Detecting a gas leak early is vital to prevent potentially dangerous situations. Common signs of a gas leak include a distinct smell of gas, a hissing or whistling sound near a gas appliance or pipe, and visible damage to a gas pipe or connection. Additionally, you may notice bubbles in water or dead vegetation around an outdoor gas line.

If you suspect a gas leak, you should act immediately. First, turn off the gas supply at the meter if it is safe to do so. Open all windows and doors to ventilate the area. Do not use electrical switches, mobile phones, or anything that could cause a spark.

Leave the property and call the National Gas Emergency Service on 0800 111 999 from a safe location. Do not return to the property until it has been declared safe by a qualified professional. If you feel unwell and suspect carbon monoxide poisoning, seek medical attention immediately.

Electricians working in the UK should be certified specifically to guarantee their suitability for safe electrical job completion.

Being a member of a competent person scheme indicates that the electrician has been evaluated to determine whether or not they are capable of meeting the requirements that are required. They are able to prove to themselves that their work is in accordance with the Building Regulations.

Particularly critical for some kinds of work, such as the installation of new consumer units or circuits, this is a crucial consideration.

As the IET Wiring Regulations (BS 7671) are the regulations that determine the standard for electrical installations in the United Kingdom, it is also beneficial for electricians to have a current understanding of these regulations.

Using the websites of the appropriate competent person schemes, you are able to verify the qualifications and registrations of an electrician before you hire them.

Verifying that your gas engineer is registered with the Gas Safe Register is the best way to confirm that they are qualified to work safely on gas appliances. You can accomplish this by going to the website of the Gas Safe Register and making use of the “Check an Engineer” option that they provide.

Enter the ID number of the engineer or the name of the company to see whether or not they are registered.

You also have the option of requesting to view the Gas Safe ID card of the engineer when they arrive. This card has their photo, a one-of-a-kind licence number, and a list of the several types of gas work that they are qualified to conduct.

You should also check the back of the card to confirm the specific appliances that they are qualified to work on in order to make sure the information is current.

While it is against the law for unregistered individuals to work on gas appliances, it is essential to make use of a Gas Safe-qualified engineer. You may protect yourself from potentially life-threatening problems that could be caused by poor gas work by making sure that your engineer is registered.

The residual current device, often known as an RCD, is an essential safety device that is designed to guard against electric shock and to limit the risk of electrical fires among people. When it detects an imbalance in the flow of electricity in a circuit, which may be an indication of a problem or leakage current, it immediately cuts off the power supply. This is how it functions.

The use of RCDs is necessary for the protection of both individuals and property. As a result of their ability to respond to potentially hazardous circumstances in a matter of milliseconds, they offer a high level of protection. Consequently, this can prevent electric shocks from causing significant injuries or even fatalities.

Recurrent circuit breakers (RCDs) have the capability to lessen the likelihood of electrical fires by identifying faults that may result in overheating and igniting.

According to the IET Wiring Regulations (BS 7671), the installation of recurrent circuit breakers (RCDs) is mandatory in the United Kingdom for any new electrical installations. or significant alterations.

It is also suggested to include RCD protection for installations that are already in place, particularly for circuits that feed portable equipment or installations that are located outside.

There is a legal obligation placed on landlords in the United Kingdom to ensure that rental homes are safe from electrical hazards. As part of this, electrical installations are subjected to routine inspections and analyses.

The Electrical Safety Standards in the Private Rented Sector (England) Regulations 2020 stipulate that landlords are required to have the electrical systems in their homes in order to comply with the regulations. inspected and tested at least every five years by a qualified and competent person.

Tenants are entitled to get a copy of the electrical safety report, also known as the Electrical Installation Condition Report (EICR), from their landlords within a period of 28 days following the inspection. If the local government makes a request for a copy, they are also required to provide one.

According to the report, any corrective work that is necessary to meet the safety criteria must be finished within a period of 28 days, or sooner if it is mentioned in the report.

Failure to comply with these requirements may result in monetary fines as well as action taken by the authorities in charge of its enforcement. If a landlord wants to safeguard their tenants from injury and decrease the possibility of electrical hazards, one of the most important obligations they have is to make sure that their electrical systems are safe.

The use of an electrician or gas engineer who is not qualified poses considerable dangers to both the safety of individuals and the property. Those who are not qualified may be lacking in the information, abilities, and experience that are required to carry out the work in a manner that is both safe and up to the standards that are expected.

This can result in severe defects such as electrical shorts, gas leaks, or faulty installations, all of which have the potential to cause fires, explosions, or carbon monoxide poisoning.

Performing electrical work in an improper manner can result in electric shocks, fires, and damage to both property and residential appliances. Electrical problems are a prominent source of fires in homes, and it is important to note that improperly conducted work considerably increases the danger of electrical fires.

In a similar vein, gas work when carried out by someone who lacks the necessary qualifications can result in gas leaks and carbon monoxide poisoning, both of which can be lethal.

Employing personnel who lack the necessary qualifications may result in a failure to comply with legal and insurance requirements. Should an event take place, it is possible that insurance claims will be rejected, and property owners may be subject to legal liabilities.

When it comes to ensuring safety and compliance, it is always vital to verify the qualifications and registrations of gas engineers and electricians.

Portable heaters have the potential to be an efficient method of providing additional warmth; however, they must be utilised in a safe manner in order to avoid accidents and hazards. Portable heaters should always be placed on a level, sturdy surface that is located away from places with a lot of foot traffic in order to prevent them from being knocked over.

Make sure that they are maintained at a distance of at least one metre from substances that can catch fire, such as paper, curtains, and furniture.

Always make sure to switch off a portable heater before leaving the room or going to sleep, and never leave it unattended. When it comes to use and maintenance, it is of the utmost importance to adhere to the instructions provided by the manufacturer. This includes performing routine cleaning to prevent the accumulation of dust, which can pose a risk of fire.

Make use of heaters that come equipped with safety measures such as an automated shut-off in the event that they overheat or tip over. It is important to avoid utilising extension cords with portable heaters because doing so can raise the risk of the heater overheating and causing an electrical fire.

Last but not least, check to see that your homes or places of business are equipped with smoke alarms and, if necessary, carbon monoxide detectors that are operational.

Immediately reporting any concerns you may have regarding the safety of gas is essential in order to avoid any potential hazards. Call the National Gas Emergency Service at 0800 111 999 in the event of an emergency or a gas leak that is occurring immediately. If the situation calls for it, they will offer direction and dispatch an engineer to solve the problem.

Issues that are not considered to be emergencies can be reported to the Gas Safe Register. Some examples of these issues include suspected unlawful gas work or an engineer who is not registered.

Either go to their website or phone their helpline to provide specifics about the problem you are experiencing. In order to guarantee everyone’s safety, they will conduct an investigation and take the necessary steps.

Landlords are obligated to swiftly address any problems regarding gas safety that are reported by renters. In the event that a landlord does not take action, tenants have the ability to consult with the environmental health department of their local government for assistance.

While it is necessary to take any concerns regarding gas safety seriously, it is also essential to make sure that these concerns are addressed by qualified professionals in order to keep the environment safe.

When using electrical appliances in close proximity to water, it is necessary to take preventative measures to avoid electric shocks and other potential dangers. Under no circumstances should electrical appliances and cords be placed in close proximity to water sources, such as sinks, bathtubs, or pools. First, make sure that your hands are completely dry before you handle any electrical gadgets.

Utilise only appliances that are specifically built for use in locations where water and electricity are located in close proximity to one another, such as bathrooms and kitchens. These appliances should be equipped with the appropriate safety safeguards.

Residual Current Devices (RCDs) should be installed in these places because they have the ability to swiftly cut off power in the event that a fault is discovered, hence lowering the likelihood of electricity shock.

Cords and appliances should be inspected on a regular basis for any symptoms of damage, such as fraying or cracks, and should be replaced if possible. In wet or damp situations, extension cords should be avoided since they are more prone to damage and present a greater danger of electrical problems.

The use of extension cords should be avoided. When working with electrical items in close proximity to water, it is imperative that you always adhere to the safety guidelines provided by the manufacturer.

Commercial premises should have their electrical installations inspected and tested on a regular basis to ensure that they are safe and in conformity with rules. Generally speaking, the appropriate time for such inspections is once every five years or at the conclusion of a tenancy, whichever occurs first.

In accordance with the requirements listed in the IET Wiring Regulations (BS 7671), this is the case.

An electrical installation condition report, often known as an EICR, is a document that is created by a licensed electrician to examine the electrical system for any faults, deterioration, or safety concerns. They will examine the quality of the wiring, protection devices, and other components to guarantee that they are up to date with the most recent safety regulations.

Inspecting the property on a regular basis helps discover potential dangers before they become major issues. More frequent inspections may be required for high-risk locations or for situations in which the equipment is subjected to heavy use.

These inspections are in addition to the five-yearly inspections. When a regular inspection schedule is maintained, it helps to guarantee that a safe working environment is maintained as well as compliance with legal duties.

Incorrect wiring, overloaded circuits, and broken electrical equipment are some of the potential causes of electrical fires. Other potential causes include insufficient electrical current. The usage of extension cords or power strips that are overloaded with an excessive number of devices is one of the most common causes.

These cords and strips can cause the item to overheat and catch fire.

All electrical equipment and appliances should be properly maintained and examined on a regular basis in order to reduce the risk of electrical fires. In order to prevent overloading of sockets and circuits, it is important to distribute the electrical load equally and unplug gadgets that are not being used simultaneously.

Use the appliances in accordance with the instructions provided by the manufacturer, and replace any that exhibit symptoms of wear or damage.

The installation of residual current devices, also known as RCDs, can offer an additional layer of security by rapidly cutting off power in the case of a malfunction.

There is also the possibility of preventing electrical fires by educating inhabitants on the proper way to operate electrical equipment and the significance of reporting any concerns they may have.

A Gas Safe-qualified engineer is required to carry out the installation of a new gas boiler in a residential residence. This is done to guarantee that the boiler is installed in accordance with all applicable safety requirements and standards.

During the installation, it is necessary to adhere to the instructions provided by the manufacturer as well as the relevant Building Regulations, which include the requirements for adequate ventilation and flues.

An evaluation of the property will be performed by the engineer prior to the installation in order to ascertain the type and size of boiler that is most suitable. This involves determining the state of the gas pipes, radiators, and other components that are already in place in order to guarantee compatibility and secureness.

Following the completion of the installation, the engineer will carry out exhaustive testing to guarantee that the boiler functions in a secure and effective manner. Among these are the inspection of the system for gas leaks, the verification of adequate combustion, and the evaluation of the system’s ventilation.

The engineer will provide a certificate of compliance in order to satisfy the conditions of the warranty and any further inspection requirements.

Regular inspections and maintenance performed by a certified electrician are required in order to guarantee that the electrical system in your home is in accordance with the safety regulations in the United Kingdom.

At the very least, an Electrical Installation Condition Report (EICR) ought to be carried out once every ten years for homes that are occupied by the owner and once every five years for buildings that are used for rental purposes.

Be certain that any electrical work that is performed in your home is carried out by a registered electrician who is a member of a competent person scheme, such as NICEIC or NAPIT. They have the ability to vouch for the fact that the work is in accordance with the Building Regulations and the IET Wiring Regulations (BS 7671).

Maintain your electrical system by using appliances in accordance with the instructions provided by the manufacturer, avoiding overloading sockets, and checking for signs of wear or damage on a regular basis.

This will allow you to schedule professional inspections. Installing recurrent circuit breakers (RCDs) and making sure smoke alarms are operational are two more ways to improve safety and compliance.

One of the most significant and potentially fatal risks associated with gas appliances that are not properly maintained or ventilated is the possibility of carbon monoxide poisoning, sometimes known as CO poisoning.

Carbon monoxide is a gas that is odourless and colourless, and it has the potential to produce symptoms such as nausea, dizziness, and headaches. In extreme circumstances, it can even cause unconsciousness and death.

Having a Gas Safe licensed engineer perform routine maintenance on gas appliances in order to verify that they are running correctly and safely is an important step in preventing carbon monoxide poisoning.

Homeowners can add an extra layer of security to their homes by installing carbon monoxide alarms, which will notify them when the gas is present.

Make sure that your home has sufficient ventilation and that the flues and chimneys are devoid of any obstructions at all times. Immediately seek some fresh air and get in touch with emergency services if you are experiencing symptoms of carbon monoxide poisoning.

Regular maintenance and vigilance are crucial to preventing carbon monoxide poisoning and ensuring the safety of the living environment.

If an electrical appliance begins to emit smoke or sparks, it is imperative to act promptly to prevent the occurrence of a fire. Unplug the appliance and immediately turn it off if it is safe to do so. You should refrain from attempting to operate the appliance until it has been inspected and repaired by a qualified professional.

A circuit breaker should be used to turn off the electricity to the appliance if it is hardwired and cannot be simply unplugged. When attempting to put out an electrical fire, you should avoid using water because doing so can result in an electric shock.

However, if you have access to a dry powder or CO2 fire extinguisher and it is safe to do so, you should use one instead.

Identifying the source of the problem requires contacting a certified electrician who will evaluate both the device and the electrical system.

One way to help prevent occurrences like these is to do routine maintenance on appliances and make sure they are operated in accordance with the instructions provided by the manufacturer.

Taking fast action to ensure safety is essential in the event that you detect the odour of gas but are unable to identify its origin. There is no use for any electrical switches, cell phones, or anything else that could potentially generate a spark.

Once the area has been ventilated, all of the windows and doors should be opened, and the gas supply should be turned off at the meter if it is safe to do so.

Immediately leave the premises and phone the National Gas Emergency Service at 0800 111 999 from a secure place. Instructions will be provided, and an engineer will be dispatched to analyse the problem. Please refrain from going back to the location until the emergency services have determined that it is safe to do so.

Gas leaks can be prevented, and early detection can be ensured by installing gas detectors and performing routine maintenance on gas appliances. These procedures, in addition to the ones listed above, can help avoid gas leaks.

If regular maintenance is carried out and prompt action is taken when a petrol odour is detected, potentially dangerous situations can be avoided.

There are special laws in place in the United Kingdom to ensure the safety of gas and electrical systems in rental accommodation. At the outset of a tenancy, landlords are obligated to ensure that electrical installations are safe, and they are also responsible for maintaining these installations for the duration of the rental.

Landlords are required to have their electrical installations inspected and tested by a trained individual at least once every five years, as stipulated by the Electrical Safety Standards in the Private Rented Sector (England) Regulations 2020.

The landlord is required to do a gas safety inspection on all gas appliances and flues in their rental premises on an annual basis for the purpose of ensuring gas safety. There is a need that this inspection be carried out by a Gas Safe registered engineer.

Within twenty-eight days of the check or at the beginning of a new tenancy, landlords are required to give renters a copy of the gas safety record.

Failure to comply with these requirements may result in severe penalties, such as monetary fines and legal action being taken against the entity in question.

Protecting renters and meeting your legal obligations as a landlord requires that you make certain that you are in compliance with the standards for gas and electrical safety.

Monitoring the safety of your gas appliances on a regular basis offers a multitude of advantages, including guaranteeing their safety and efficiency. An annual inspection performed by a Gas Safe-trained engineer helps to identify and fix possible problems before they become serious.

This helps to reduce the danger of gas leaks, carbon monoxide poisoning, and other hazards.

Regular inspections can also improve the efficiency of your gas appliances, which may result in cheaper monthly energy bills and an increase in the equipment’s lifespan. Making sure appliances are operating correctly and efficiently can help prevent costly future repairs and replacements.

Regular gas safety checks provide you the peace of mind that comes from knowing that your home is safe and complies with the regulations that are in place. Legal penalties can be avoided, and renters’ safety can be ensured by these measures, which are essential for landlords and help them avoid legal penalties.

Homeowners who want their homes to be safe and functional must perform routine maintenance and safety inspections.